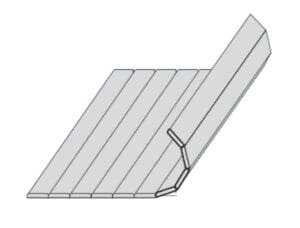

Flexbamboo Installation Instructions

(Rolls of Flexbamboo with fabric backing for wall/ceiling application)

General Information, prior to installation

- Flexbamboo is a flexible roll or sheet of bamboo strips glued to a fabric backing.

- Flexbamboo must be acclimatised for at least 48 hours in the room where the material is to be installed, at a temperature of 18o-21oC (40-65% air humidity).

- The surface on which Flexbamboo will be fixed to must have a minimum temperature of 18oC. The surface should be flat/level, without cracks, dry and clean – and in sound condition.

- If residual moisture is present in (new) plaster, a waiting/drying period must be considered. Rising damp or dampness caused by constructional faults must be eliminated at its source.

- The surface must be strong enough to support Flexbamboo. This means that the plaster must be able to absorb the tension that occurs during drying.

- Loose surfaces must be secured. For this, use a primer that penetrates the surface. Under no circumstances should the product form a film on the surface that would completely seal off the surface.

- The adhesive must be able to penetrate the surface. If the plaster is completely closed off (by paint, for example), a correct connection between the substrate and Flexbamboo is impossible. Surfaces that are too closed should be roughened up. If the surface is too absorbent, a primer or fixative should be used that penetrates the surface.

- Due to the production method, it is possible that the rolls are not entirely square to the side. Maximum tolerance here is 5mm over 1 metre. Make sure there is an oversize when installing so that the edges can be sawn straight.

Please note:

Bamboo is a natural product!

Therefore, variations in colour and structure within a batch are possible. Before installation, we advise you to inspect the material for moisture content, size, colour differences and damage. We cannot accept any complaints regarding this once the material has been installed or further processed.

Ideal room conditions

Room temperature approx. 18-21C, air humidity 40-65%.

Where these conditions are not maintained, warping, shrinkage and movement of Flexbamboo may occur. You can check the air humidity using a hygrometer and correct the humidity as required via ventilation or with a humidifier/dehumidifier.

Installation

- Flexbamboo should be fully glued on the surface. Use a glue with little or no moisture, for example a silane glue, or a dispersion glue with low water content – one that dries with a clear finish. ATTENTION: don’t apply more than 250350gm/m2!

- To cut between the strips, use a sharp knife.

- To shorten the strips, you can use a circular saw or a jigsaw. Always use a sharp saw with fine teeth.

- Glue sections of approximately 1.5 metres at a time. In this way, Flexbamboo is easy to install and will not move or loosen.

- The adhesive can be applied to the bamboo or to the wall.

- Let the adhesive dry for 10-15 minutes before applying Flexbamboo, following the glue instructions of the manufacturer.

- When applying Flexbamboo, you can still move the strips of the placed part to fit well against the previous piece.

Pressing/Gluing

- In case Flexbamboo needs to be pressed on a carrier material (MDF, chipboard etc) it should always be done in a “sandwich” – construction (3-ply) to maintain the balance in the total panel and avoid bending.

- The glue quantity and pressed method depends on the absorption of the carrier panel.

- Recommended adhesives: PVAC with low water content or PU glue.

- When pressed under high pressure and high temperature a considerable cooling time should be taken into account before stacking the cooled (max 60oC) panels.

Finish

- Unfinished Flexbamboo should be either lacquered, oiled or waxed. For oil: note that bamboo has a dense surface structure, therefore apply oil thinly and allow to dry between applications.

- Remove glue residues and other materials from the surface of the installed material. Clean the material, using a brush, sanding, or vacuum cleaner and after that a damp cloth.

- Apply the finish following the instructions of the supplier.

Additional note: Whilst all due care is taken to ensure the accuracy of these installation instructions, different and individual circumstances (eg location, substrate and installation procedures) may vary and are beyond the manufacturer’s control.

In case of doubt, therefore, consult your installer or distributor. These instructions are subject to change.