“Floating” Installation instructions (over an underlay)

Pre-installation

To allow acclimatization to the installation environment, lay your bamboo flooring flat in the room in which it is to be installed for at least 48 hours, in its packaging, at a room temperature of 18°-21°C (40-65% air humidity)

Prior to installation of any floor, the installer must ensure that the job site and sub-floor meet the following requirements:

• Bamboo flooring should be one of the last items installed in any new construction or renovation project

• All work involving water or moisture should be completed well before installing bamboo flooring. The room temperature and humidity of the installation area should be consistent with normal, year-round living conditions for at least a week before flooring installation. Room temperature of 15-20 degrees Celsius and humidity of 40- 65% are recommended.

• Unless the sub-floor and bamboo are properly sealed, bamboo flooring may not be suitable for bathrooms or laundries (due to the higher room humidity). Please refer to the Plantation Warranty conditions when installing in a wet area.

• During installation special precautions to seal sides and ends of cut boards should be taken where water may enter, e.g. bathroom, laundry and external doors and windows.

• Don’t store loose bamboo boards directly on concrete or near outside walls, long-term.•

Please see the handy builder/homeowner checklist page with a list of considerations for a floating bamboo floor installation.

Sub-floor must be:

• Structurally sound

• Clean – thoroughly swept and completely free of all debris; free of wax, grease, paint, sealers, old adhesive and other substances

• Level – flat to 3mm per 3 metres radius

• Dry (and will remain dry year-round)

It is strongly recommended that skirting boards are at least 15mm thickness (to allow for the natural expansion and contraction of the floor). Skirting boards should be fixed to the walls only after the flooring installation is complete (ie, be removed during installation).

Inspection

Bamboo is a natural product! Therefore variation in colour and structure within a batch is possible.

You should always mix the components from different boxes to create a random look.

Plantation bamboo floors are manufactured in accordance with accepted industry standards which permit a defect tolerance not to exceed 5%. These defects may be the result of a manufacturing or naturally occurring characteristics of the material.

It is recommended that at least a 5% cutting or grading allowance be added to the total square meterage when calculating the quantity of bamboo flooring required.

Carefully examine the bamboo flooring for:

• Grade, colour and style

• Finish, quality and straightness

NOTE: Plantation cannot accept any responsibility for the installation of flooring with visible defects.

Underfloor Heating: If installing over underfloor heating, ensure the underfloor heating guidelines are followed.

Installing near a water source? If installing the bamboo flooring within 1.5 metres of a water source (eg kitchen sink), please refer to the information and instructions around this here.

Installation – tools You will need:

• Tape measure and pencil

• Chalk line

• Hand saw (power saw also helpful)

• Tapping block (trimmed piece of flooring)

• Crow bar or pull bar

• Bamboo or plastic spacers(1⁄4”)

• Hammer

• Drop saw and a hand saw (power saw also helpful)

• Chocking wedges Floating installation Roberts Harmony 3 in 1Underlay (or similar)

Installation requirements

Bamboo and wood are natural products which are affected by air humidity. Excessive air humidity causes bamboo materials to swell whilst low air humidity results in shrinking.

It is of the utmost importance that you maintain distance (expansion gap) from walls, door frames, pipes etc. This distance should be a minimum of 10mm.

If the floor is wider than approx. 8 metres or longer than approx. 12 metres, or when the floor is installed in more than one room a dilatation (expansion) gap should be placed.

Also leave expansion space where the flooring will meet any vertical obstacle, such as stairs, pipes, door sills, tiles, cabinets etc. The quality of your floor installation is dependent on the quality and preparation of the sub-floor.

Please read the following carefully.

Acceptable subfloor types:

• Existing wood floor; or Plywood (10 mm minimum)

• Resilient tile and sheet vinyl

• Sub-floor grade particle board

• Concrete slab or Ceramic tile

Procedure For floating floors

(the most common method in NZ)

• Check Plantation bamboo flooring box on delivery to confirm colour and type

• Check the floor with a straight edge and mark depressions and high spots. Rectify if necessary with ‘level crete’ levelling compound or grinder

• Clean floor of paint, plaster, cement splashes, dust, oil, grease etc. Sweep or vacuum

• Plantation recommends the use of Harmony 3 in 1 Underlay when floating the bamboo flooring. Harmony provides an excellent moisture barrier, sound reduction and cushioning required for proper installation

NOTE: It is important and best practice to install the floating bamboo floor around kitchen cabinetry (rather than under it), to allow the floor to expand and contract naturally.

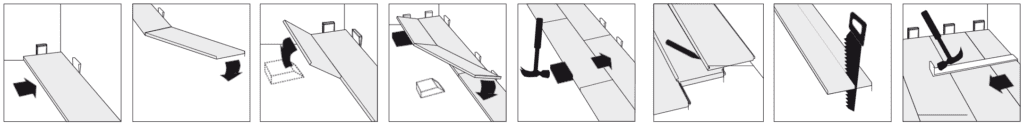

Step-by-step installation

Roll out and overlap the Harmony 3 in 1 Underlay using the adhesive strips. Ensure that the underlay wraps over the exposed edges of the flooring by 20mm. This will be covered over when skirting boards are installed. Please refer to the Manufacturer Robertsfor further information.

1. To ensure a perfect expansion joint, saw off the tongue along the edge that will go against the wall

2. Start in a corner of the room with the locking strip (groove end) facing the room

3. Set the first board in place with the long side tongue parallel to the starting wall, spaced about 15cm away from the wall. Set a spacer against the left hand wall, and nudge the left edge of the board against it.

Set the second board into place. Hold it at a 45 degree angle to the first, and engage the left hand butt joint of the second board with the right hand butt joint of the first. When the joint is fully engaged, lower the second board to the floor and the joint will lock. Complete the first row in this fashion, cutting a board to fit at the end of the row (remember to allow expansion space at the far end of the row).

4. Begin the second row with the off-cut from the first, if it is longer than 300mm. Line up the left-hand end with the previous row and engage the long side joint. Do not press the new board flat; instead, insert the installation wedge about 150mm from the right-hand end so that the board is lifted at an angle.

5. Take the next board and engage the end joint with the raised end joint of the previous board. Lay the new board down so that its long side joint is lined up with the previous row. Remove the installation wedge and, using the tapping block, tap along the long side joint of the new board while gently pressing down on it to lock the long side joint to the previous row.

NOTE: always use a tapping block when tapping boards together. Do not use a hammer as it will damage the joint.

6. Repeat this procedure for all subsequent boards. Ensure that all butt joints are staggered by a minimum of 500mm and do not use boards less than 300mm in length.

7. Continue installing in this manner until you have completed three or four full rows. Insert a series of expansion spacers along the starting wall and slide the assembled flooring against the starting wall.

NOTE: It’s more practical to fine tune the gap between the long sides and the wall after the first 3-4 rows have been laid.

8. Continue with the installation throughout the rest of the room. Start rows with a variety of different lengths of boards. You can also use off cuts from previous row ends to begin new rows, as long as they are a minimum 300mm in length. If a board is too short or there is no piece left over, start with a new board cut in half.

9. When an entire row is completed, remove all the wedges and review the row to ensure that there is no gapping and that all locking mechanisms are fully engaged (all boards are perfectly flat). Use a rubber hammer and a tapping block to ensure that all edges fit tightly. Remember to stagger butt joints by at least 500mm.

10. To measure the width of the last row of boards, place the board face down, tongue side facing the wall, on top of the last installed row. Place a spare board on top of the board to be cut, slide the spare board across until it touches the wall. Run a pencil down the edge of the spare board, thus marking the board to be cut. Remember to allow for extra space for the expansion gap.

11. Cut (“rip”) the board along the pencil line.

12. Tap the last board into place using a hammer and a hook tool. Insert spacers to obtain the required expansion gap.

13. In some areas it may not be possible to tilt the boards enough to engage the locking mechanism and have the boards correctly locked together (eg under an undercut door frame). In these circumstances it is suggested to either: – trim off the tongues of the board to enable the two boards to join, then glue the boards at the join, and underneath – after removing a piece of underlay (if “floating” the floor), so that the boards are fixed to the sub-floor – providing an adequate expansion gap of at least 8mm in all directions around the perimeter of the floor; or – trim off the tongues of the boards to be joined and apply a thin layer of wood glue, then tap the boards together gently until they are joined firmly. Wipe off any excess glue.

It is suggested to remove the layer of wax coating on the edges of the boards with fine wire-wool or sand-paper – so that the glue will adhere sufficiently.

NOTE: Never hammer boards without using a tapping block as damage to the boards may occur.

Finishing

After installing the floor you can immediately walk on it and begin the finishing process.

Please allow the floor to settle for 24 hours before heavy objects and excessive foot traffic are placed on it.

1. Remove all the spacer blocks/wedges

2. Fix the skirting boards over the underlay sticking up from the floor

NOTE: Never fix the skirting boards to the floor itself – allow for the floor to expand and contract underneath the skirting board

3. Finish any radiator/floor pipes with silicone

4. In places where profiles or skirting boards can’t be used, fill the expansion with silicone or preferably scotia, to hide the gaps.

5. Silicone should also be inserted into the expansion at the perimeter where the flooring may be exposed to excess moisture, e.g. dishwashers, sinks, entrance to bathrooms, laundries

6. Before you move furniture onto the floor, take a moment to protect your new floor by putting felt pads on all furniture and accessories.

Finishing Trim

Where the bamboo flooring transitions to another floor type (i.e. carpet, lino, tiles), or meets an outside door or window, the use of a ‘U-Channel’ is recommended.

These can be purchased from most flooring wholesalers or hardware stores.

NOTE: A U-Channel allows both the underlay and bamboo flooring to slide into the bar, securing the loose (floated edge) and allowing for expansion and contraction of the bamboo flooring.

Cleaning and care of bamboo flooring

Look after your bamboo flooring, in the same manner, you would a regular timber hardwood floor.

Caring for your bamboo floor:

• Vacuum or sweep regularly

• Remove spills promptly

• Place mats at exterior doors to trap sand and grit from incoming traffic

• Install padded felt on furniture feet

• When moving heavy furniture or appliances, always pick up the furniture rather than sliding it across the floor

• Keep pet’s claws trimmed to avoid excess scratching and gouges

Cleaning of your bamboo floor:

• Sweep up dust with a clean static mop or micro-fibre mop (eg Bona Wood spay mop), or vacuum (soft brush)

• Use undiluted methylated spirits to remove any stubborn stains (red wine, coffee etc)

• Use undiluted methylated spirits or briwax to remove any light marks or scrapes/scratches

Tip: the nut of a walnut rubbed into minor scratches is quite effective at hiding minor scratches, as is a hardwood floor cleaner buffed into the floor.

• Put your cleaning products into a spray bottle so that you can control the amount you use.

What NOT to do:

• Do not let sand, dirt or grit build up

• Do not wet mop or use abrasive pads to clean/scrub floor

• Do not use wax, oil, soap or abrasive household cleaners on your floor. The use of these products can dull the floor finish and make refinishing difficult

• Do not roll or slide heavy furniture or appliances across your floor

• When vacuuming the floor never use a solid head. Always use a brush head on bamboo flooring

• Do not use a steamer on your bamboo floor.